Aug 4, 2022Family, dedication fuel Georgia onion grower’s success

Hard work and a do-it-yourself attitude helped make McLain Farms Inc. a successful grower of Vidalia sweet onions.

Exponentially rising costs, however, press the business, which has grown onions since the mid-1980s.

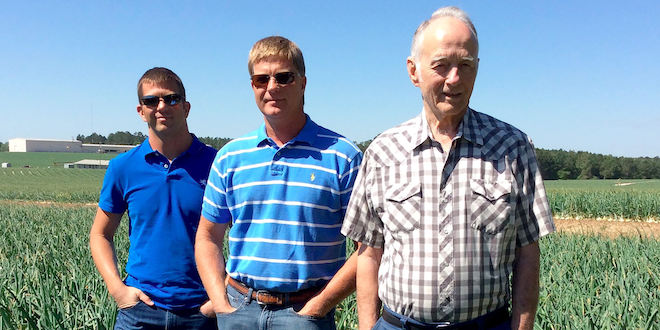

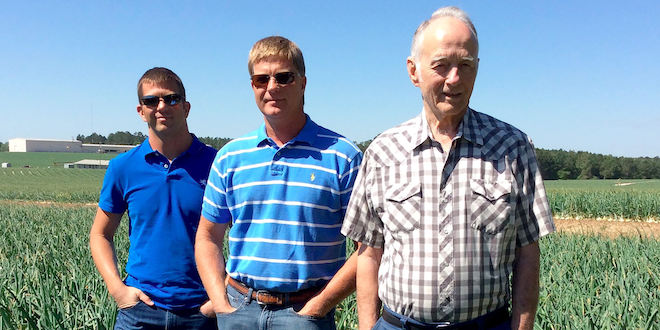

Brothers Brett and Rusty McLain and their spouses run the Lyons, Georgia, farming operation of 400 acres of conventional and organic Vidalias.

“This year, the supply chain crisis has thrown a huge curveball in the price of everything,” Brett McLain said.

A forklift has remained on order since July 2021 and isn’t expected to arrive until October. Standard parts for electric motors, breakers and more gearboxes used to arrive the next day. It now may be a month to two months.

Brett McLain said that farming takes dedication and sacrifice.

“We dedicated our lives to this farm,” he said. “We worked ridiculous amounts of hours, which is what it took to get this whole thing rolling and growing to the point where it has been. You have to maintain that dedication to feed the monster, so to speak.”

That dedication requires meticulous attention to detail. Brett McLain handles a lot of field work and his brother runs the packing shed.

“We would rather be hands-on,” Brett McLain said. “It’s really neat being in a field working on a tractor and looking over and seeing your son right beside you on another tractor. It’s one of the coolest things I’ve ever seen.”

Farming heritage

The brothers grew up farming alongside their father, James. When he was 10, Brett McLain started working on the family’s tobacco farm, as did his younger brother later. Their grandparents also grew cotton, row crops and raised livestock. Spring breaks, summers and other times away from school found the brothers working the farm. In 1991, while in his early 20s, Brett joined full-time, and Rusty started full-time in 1992, packing onions.

The farming family planted its first crop of Vidalias in 1986, and until 1994, when it constructed its first controlled- atmosphere cooler, focused on onions and tobacco. Because of the stress of producing both crops, the sons asked their dad to choose one. From then on, it was all onions.

In 2010, the brothers took over the family business. with their father becoming a consultant. James McLain died in 2018; he was 77.

McLain Farms was recognized as Vidalia Grower of the Year award in 2014, 2018 and 2021.

The McLain brothers are teaching their children – Brett’s son and daughter and Rusty’s son – about running the farm, and they are considering agricultural careers. Jessica, Rusty’s wife, handles human resources and compliance, while Kim, Brett’s wife, manages farm accounting and payroll.

Family involvement is important in southeast Georgia, where the number of Vidalia onion growers has declined by more than half over the past 30 years.

“The future really depends on this next generation,” Rusty McLain said. “Someone has to grow the food for all these people to eat. It’s a really tough life. I honestly don’t know what things will look like 20 years from now.”

Keeping it manageable

One key to success is making sure acreage doesn’t get out of control.

“It’s always a competition amongst ourselves to see the least number of rejections in a year,” Brett McLain said. “We don’t want to have any complaints or problems. That involves keeping your acreage reasonable so you can keep up with it.

“If you get too big and get too many acres and get too spread out, you can’t get the detail you need to make quality top-notch onions,” he said.

Timing is critical, from planting to spraying, harvesting and packing.

“Everything has to be done in a timely manner,” Brett McLain said. “If you over-extend yourself and get more of what you can, then something’s going to start to slip. It’s tough keeping yourself reigned in.”

While planting and harvesting remain similar to the past, the McLains have taken steps to streamline other processes. Unlike other onion crops that can be seeded and harvested mechanically, Vidalias require hand-planting.

The McLains reduced fertilizer and spray applications. They apply fertilizer and lime through variable rates, to areas requiring more or less volume. Technology has also improved soil sampling.

“What we have seen over the years and one thing we strive for is a more uniform crop, more consistent sizing and better yields,” Brett McLain said.

The McLains cooperate with seed companies to grow better varieties through test plot trials. “The seed companies keep bringing us new and improved varieties that help us across the board,” he said. “We couldn’t do what we do if we were using the same varieties we planted 20 years ago which just don’t work anymore.”

A graveyard of failed experimental equipment is a testament to the McLains’ openness to new ideas.

“We have a lot of homemade (equipment) that did work, but have never been afraid to try something,” Brett McLain said.

As harvest nears every spring, Vidalia onion growers keep a close eye on the crop.

“Things can change so fast, especially in the springtime, when you’re close to being ready for harvest,” he said. “You could have a really good crop today, but tomorrow you could be in a lot of trouble.”

Family is the defining characteristic of McLain Farms.

“We couldn’t do this alone,” Brett McLain. “It’s too big with too much going on with way too much to do. Family is the most important thing to us anyway. All this could go away tomorrow, but our families would stay together.”

— Doug Ohlemeier, assistant editor