Local craftsmen demonstrate mastery on custom smoker

John, a local Bandera resident, has been barbecuing at home for as long as he can remember. After visiting a BBQ restaurant featured on an episode of his favorite show, BBQ Pitmasters, John had a concept for a customized smoker to be built on his property.

After drawing up his own design and asking local businesses for resources to build his smoker, he was put in touch with Tim Gard, a local contractor. Working with trusted tradesmen, Tim brought in Jason Clark with CXC Welding to build the iron bones that would be the smoker box, Anthony Rodriguez to lay the concrete pad, Pablo Amaya to construct the stonework around the smoker, Frank Garza & Gabriel Rodriguez with Garza Granite to install the granite tops and Javier Renteria to finish the paint touches.

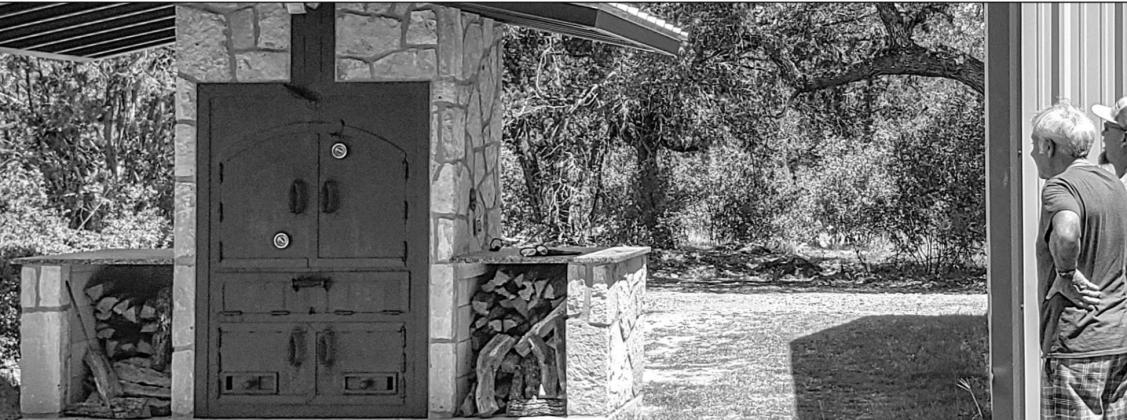

Years of welding experience from Clark and his team offered tweaks to John’s design in order to enhance the overall function of the smoker capabilities. The smoker has a double door with three large meat racks that pull out. There are two thermometers, one at top rack height and one at lower rack height, to monitor the internal temperatures and their distributed consistency.

The gauges have ports for Bluetooth so temperatures can be tracked on John’s phone. There are even flues incorporated in the handles of the doors. Beneath the racks is a receptacle for a seven-inch deep-water tray that pulls out.

A metal bar above the tray serves as an indicator to properly center the water tray underneath the racks for even diffusion of moisture to the meats. The double-door firebox below the water tray, where the wood is fired up and stoked, has adjustable vents. The steel iron frame has firebrick cut inside and vents both in front and in back.

The colossal smoker stands seven feet high from concrete to the top of the stone build. The metal roof atop the structure was designed to match the height and type of the neighboring bunk house and its capped chimney has an adjustable damper. Below the roof is a motion-activated spotlight for night barbecuing. Granite counter tops for prep are installed on each side of the steel iron oven, each undergirded by a sizeable compartment for wood storage.

John strived to give recognition to the efforts of each involved in the creation of his uniquely customized smoker that took about four months to finish. He expressed his appreciation for the hard work and talent that the men executed. John explained

“These guys added details to my own design. How many people will do this on their own initiative, much less in this county of ours, which is so small? Tim got all the raw material and delivered them in. Pablo broke every stone with his little chisel and fit them in place. Jason built the iron box at his shop with his son and took a personal interest in it,” said John.

“He got very carried away,” Gard laughed. “John wanted something badass, and I like to give people what they want. It takestime to make something right into a masterpiece and you can’t rush talent. We did elaborate a little bit on John’s design but it was really my subs. They made me look good. They are the best in the county across the board and I love ‘em all like family.”

Garza expressed, “It was an awesome experience working on a one-of-a-kind vault BBQ pit.”

Rodriguez added it was a wonderful experience to work on a unique project out in the beautiful Hill Country.

Clark, who runs his welding business with his wife and sons, did the ironwork at the Best Western Hotel and the Trail Boss Restaurant, among other locations.

“A lot of what we do is all custom work. I add my little touch to it to make it unique. The more people see what we do, well, we are just swamped now. John wanted everything symmetrical, and we kept it there. Now, that smoker cooks so well, it’s like a convection oven. John told me that a brisket that used to take 11 hours now takes eight hours,” said Clark.

Gard has a message for the newcomers to town. He stressed that if you are looking to get work done, don’t look online. Ask around in the community. They will lead you to the right people – the ones that are known for their integrity and quality. It’s all word-of-mouth.