Abstract

Polypropylene fibres are difficult to dye using commonly used techniques due to the high crystallinity and non-polar aliphatic structure, that lack reactive places for dyes in the molecule. Dyeing PP fabric in scCO2 with antibacterial dyes merged the dyeing and finishing methods, resulting in a more productive technique in terms of water and energy consumption. Unmodified polypropylene fabric was dyed with 4-[2-[4-(ethenylsulphonyl)phenyl]diazenyl]-N,N-diethylbenzenamine antibacterial dye under scCO2 medium. The influences of scCO2 working parameters, such as dye concentration, pressure, dyeing time, and temperature, on fabric dye absorption expressed as color strength were studied. The color strength (K/S) was measured as well as CIELAB color parameters. The results were compared with its water dyeing analogue and it was observed that color strength as well as color depth (L) of the samples dyed in scCO2 were noticeably better than its water counterpart. In both scCO2 and water, the fastness properties (washing, rubbing, and light) of the dyed samples were excellent. Antibacterial activity of the dyed polypropylene sample in scCO2 was estimated and the results indicated good antibacterial efficiency.

Similar content being viewed by others

Introduction

Polypropylene (PP) has various excellent properties, such as low density, good anti-static characteristics, high toughness and resilience, zero water adsorption, high tensile strength and excellent environmental resistance. PP is useful for home-furnishing and industrial applications1,2. Because of the low dyeability of conventional dyeing methods, its demand in clothing is limited3. Due to the high crystallinity and non-polar aliphatic structure of PP, which lacks reactive places for dyes in the molecule, the fibres are difficult to dye using traditional techniques.

Much research has been reported to overcome this problem4,5,6,7 and to improve the dyeability of PP fibers. The application of novel polymer additives8 changed the positive characteristics of PP fibers. Another method is using low temperature plasma technique to improve dyeability of PP6. Sahinbaskan et. al. studied the use of microwave energy for dyeing polypropylene9 while Toshniwal et. al. has produced nanocomposite PP by utilizing nanoclay modified with quaternary ammonium salt, which can be dyed with both acid and disperse dyes10. Although modifications of PP fabrics have made it probable to dye.

Water shortage has recently prompted the development of new technologies for textile chemical wet processing that use as little water as possible11,12,13,14. The use of scCO2 fluid (SCF) allows for an anhydrous dyeing process with numerous advantages. This substance, when highly compressed, can have the properties of both a liquid and a gas. Using supercritical carbon dioxide instead of water as a dyeing medium provides numerous environmental benefits in the textile industry, including zero waste emission, a high uptake rate, and low energy consumption15,16. Multiple research papers mentioned that scCO2 could be successfully used for the dyeing of natural and synthetic fabrics17,18,19,20,21,22,23.

Dyeing PP fabric in scCO2 with antibacterial dyes merged the dyeing and finishing methods. In view of our efforts to dye synthetic fabrics in scCO224,25,26,27,28,29,30 especially PP, we have previously succeeded in developing a new method for dyeing PP fabrics with disperse dyes under aqueous and scCO2 medium. It was noticed that the color strength of the dyed PP fibres in scCO2 was found to be higher than in water. The fastness properties (washing, light, rubbing) of the dyed samples under study in scCO2 and water were excellent31. Sulfone derivatives provide an example of an important class of bioactive compounds. Literature described sulfone as anti-fungal32, anti-inflammatory33, anti-HIV34, anti-tubercular35, anti-cancer36, anti-hepatitis37 and anti-tumor38 agents.

In continuation of our work, we report here on a one- step dyeing and antibacterial finishing of PP fabrics with synthesized disperse reactive dye containing sulfonyl functional group under scCO2 medium.

Experimental sections

Materials and dyes

Dyes

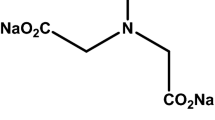

The orange antibacterial vinyl sulfone disperse reactive dye (Fig. 1) was produced using the method previously mentioned and was prepared for use in scCO239.

Material

The dyeing substrate was a 100% unmodified polypropylene fabric provided by Shikisen-sha Company (Osaka, Japan). Crystallinity of polypropylene fabrics is calculated using Eq. (1)

Δ H = melting enthalpy: 105.8 J/ g,

Δ Hm = ideal crystal melting enthalpy: 209.1 J/g (Brandrup, 1999).

Crystallinity: 50.6%

Water dyeing apparatus

Infra color dyeing system was used for water dyeing. It was composed of beakers mounted on a circular beaker carrier wheel. Heating with infrared radiation, cooling with air, and automation with the DC4 F/R microprocessor programmer. The maximum temperature reached 140 °C, with a maximum average heating rate of 5 °C/min and a maximum cooling rate of 3 °C/min.

Supercritical carbon dioxide dyeing apparatus

As shown in (Fig. 2), the main components of a scCO2 apparatus are: CO2 cylinder, a chiller (model Julabo FL601), an extraction RHPLC pump (model JASCO PU-4180), a semi-preparative CO2 pump (model JASCO PU-4386), a heater controller (model HC-2068–01), and a back pressure regulator (model JASCO BP-4340) with a maximum rate of pressure of 30 MPa, a temperature controller and speed controller (model EYELARCX-1000 H) with a maximum temperature rate of 130 °C, a dyeing autoclave with an internal capacity of approximately 50 mL, and a maximum CO2 flow rate of a circulation pump of 10 mL/min,

Procedures

Dyeing unmodified PP fabrics in water

A Laboratory-Scale Thermal HT Dyeing system with a liquor-to-goods ratio of 1:50 was used for the dyeing experiment. The dyeing was performed at a concentration of 2% dye (based on the fabric weight). Then, in the dyeing machine, a PP fabric (10 × 10 cm) was inserted. Over the duration of 45 min, the temperature was increased from 35 °C to 130 °C, and dyeing was continued at that temperature for around 1 h. The samples were dyed, then washed in a bath containing 2% nonionic detergent (Sera Fast C-RD) at 60 °C, rinsed, and dried at room temperature.

Dyeing unmodified PP fabrics in scCO2

In the beginning, (CO2) gas was cooled to -5 °C by the chiller. PP fabric (3 × 10 cm) was covered by the screw tube and was inserted in the dyeing vessel. The dye was added to the bottom of the vessel's floor, and the concentration of dyestuff used ranged from 1 to 3%. (owf). Liquid CO2 was transported from the valve to the entire system by the semi-preparative CO2 pump. The autoclave was sealed and heated until the system reached the desired pressure (15, 20, 250 MPa), temperature (100, 120, 130 °C), and dyeing time (1, 2, 3 h) in line with the study of dyeing in scCO2. The shut-off valve was slowly opened to release CO2 until the pressure in the dyeing vessel reduced and reached atmospheric pressure automatically. The dyed sample was removed from the vessel. To eliminate the remaining dyestuff on the surface of the dyed samples, they were immersed in a bath containing 2% nonionic detergent (Sera Quick CRD) at 60 °C, rinsed with water, and dried at room temperature.

Measurements and testing analysis

Color assessment

A spectrophotometer, Japan; model CM-3600 A, manufacturer KONICA MINOLTA, was used to measure the (K/S) and CIELAB color parameters (lightness (L*), Chroma (c*), hue (h*), the degree of redness (+ ve);greenness (-ve) (a*); the degree of yellowness (+ ve) and blueness (−ve).

(b*) of the dyed samples. The K/S values of dyed polypropylene fabrics were calculated using the Kubelka–Munk Eq. (2) at the wavelength of maximum absorption for vinyl sulfone dye.

The total color difference (∆E) was represented in terms of CIE LAB color space data. It was computed using Eq. (3)

Assessment of color fastness

An ISO standard method was used to analyze the dyed samples. The light fastness of the dyed PP samples was evaluated using an ISO 105-B02 Xenon arc lamp test with a standard blue scale (ISO 105-B02:2013 Part B02: Color fastness to artificial light: Xenon arc fading lamp test). The dyed PP samples were also analyzed for fastness to washing and rubbing according to ISO (International Organization for Standardization) 105-A03:1993 (ISO 105-A03:1993 Part A03: Grey scale for assessing staining) and ISO (International Organization for Standardization)105-A02:1993 (ISO 105-A02:1993 Part A02: Grey scale for assessing staining) and ISO (International Organization for Standardization)105-A02 (ISO 105-A02:1993 Part A02: Grey scale for assessing change in color).

Mechanical testing of unmodified PP fabrics

The mechanical properties of undyed and dyed PP fabrics were tested using a Tinius Olsen with a load cell 500 N, preload 0.01 N, speed 100 mm/min, and gauge length 100 mm in both scCO2 and water medium.

Antibacterial activity

Antibacterial activity assessment against Staphylococcus aureus, Bacillus cereus, Escherichia coli, Pseudomonas aeruginosa and expressed as zone of growth inhibition ZI (mm). The antibacterial activity was determined by the agar well diffusion method12.

Raman spectra of PP fabrics

Using the Jasco NRS-4500, the Raman spectra of undyed and dyed PP fabrics under scCO2 were observed in the range of 200 to 4000 cm-1.

Statistical analysis

All of the experiments were completed by averaging three (sample) readings. The standard error of the mean was determined using the Eq. (4) below, and it was discovered to be + ( −) 0.1

where SE is standard error, S is sample standard deviation, and n is the number of observations of the sample.

Results and discussion

Factors affecting dyeing properties of unmodified PP fabrics dyed in scCO2 medium

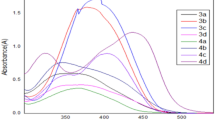

The influences of scCO2 working conditions, such as dye concentration, system pressure, dyeing time, and temperature were studied as influencing factors40,41. Values of the K/S of dyed samples were carried out in the range of (360–490 nm).

Effect of dye concentration on K/S of unmodified PP fabric dyed in scCO2 medium

At (1, 2, 3, 4%), the effect of dye concentration on (K/S) of PP fabric dyed in scCO2 was investigated. The dyeing pressure was set to 25 MPa, the temperature was set to 130 °C, the dyeing time was set to 60 min, and the dyeing medium flow rate was set to 7.500 ml/min during this procedure. As was revealed in (Fig. 3), the K/S of dyed samples in scCO2 was increased from 4.55 to 7.22 and it became constant at 4%. PP fibers have a high number of non-polar sites, which allows for multiple "Van der Waals forces" to occur, resulting in higher K/S values. The presence of alkyl chains in the structure of dyestuff made the materials more chemically alike and rely on the entropy of mixing, however, at 4%, the fabric was saturated and there is no longer increase in K/S.

Effect of system temperature on K/S of unmodified PP fabric dyed in scCO2 medium

The association between dye adsorption and system temperature (100,120, 130 °C) in scCO2 was studied as shown in (Fig. 4). The experiment was carried out at a 3% concentration, a pressure of 25 MPa, a dyeing time of 60 min, and a dyeing medium flow rate of 7.500 ml/ min. It was inferred that increasing the system temperature from 100 to 130 °C increased the K/S of PP fabrics dyed in scCO2. Increasing temperature increased the vapor pressure of the solute which lead to an increase in solubility. Additionally, the structure of the PP underwent swelling during dyeing due to high temperature and pressure which helps penetration of dye into the fiber. Also, the melting temperature of PP for most cases is about 160 to 170 °C depending on the tacticity and crystallinity of the polymer. Therefore, at 130 °C chain mobility was increased, and consequently aided the dyeing process. The result obtained was in good agreement with our previous work31.

Effect of system pressure on K/S of unmodified PP fabrics dyed in scCO2 medium

PP was dyed at a concentration of 3%, pressure varying from 15 to 25 MPa, a temperature of 130 °C, and a dyeing period of 60 min to investigate the effects of system pressure on the dye uptake of fibers. As shown in (Fig. 5), K/S values of dyed PP fabrics were improved by increasing system pressures to 15–25 MPa. Raising pressure increased the density of the scCO2 fluid, which improved the dye's solvent power and the interactions between the scCO2 medium and the intermolecular chains of the PP fibers in the dye bath31.

Effect of dyeing time on K/S of unmodified PP fabric dyed in scCO2 medium

At times ranging from 60 to 180 min, the effect of dyeing time on the adsorption of the vinyl sulfone disperse reactive dye on PP fabrics was observed. PP fabrics were dyed at 130 °C, a pressure 25 MPa, a dyeing medium flow rate of 7.500 ml/min. As presented in (Fig. 6), by increasing the time from 60 to 120 min, the K/S on PP fabric was increased, and it became constant at 180 min. This is due to low viscosity and high diffusivity of CO2 in supercritical state. As a result, it is much easier to permeate fiber than water during the dyeing process in scCO2. PP swells because of the permeation of CO2, thus causing a decrease in percent crystallinity and order which in turn improved dyeing. Therefore, the K/S values of the dyed PP were enhanced by increasing time.

Color assessment

The reflectance data and color coordinates of supercritical dyed PP samples were measured using the CIELAB method in terms of L*, a*, and b* at a concentration of 3%, pressure 25 MPa, temperature 130 °C, and dyeing time 120 min. The color coordinates were listed in Table 1. which indicated that the dyes have good affinity to PP fabrics. Positive values of b* caused the color hues of dyes on PP fabrics to shift in a yellowish direction on the yellow-blue axis. The positive values of a* mean that the color hues of the dyes on PP fabrics changed in the redness direction on the red-green axis.

Dyeing of unmodified PP fabric in scCO2, as a lower viscosity than water rendered of scCO2 capable of penetrating unmodified PP fabric thoroughly, hence resulted in a higher dye uptake compared with that using aqueous method with 3% dye concentration. In addition, the synthesized dye molecule containing an aliphatic substituent group (N, N-diethyl), which increase the solubility of the synthesized dye in scCO2, linking the dye with the unmodified PP fabric via the "Van der Waals forces"43,44. A comparison of color assessment of scCO2 and aqueous dyed fabrics showed that, without the addition of a carrier or dispersing agent, the appreciable color assessment of the dyed samples in scCO2 was significantly higher than that of the dyed samples in water.

The levelling properties of dyed unmodified polypropylene fabrics in scCO2 using the vinyl sulfone dye were illustrated in Table 1 from which it is clear that the average colour differences (ΔE, calculated from the CIE L*a*b* coordinates) of the dyed unmodified polypropylene fabrics indicated very good levelling properties in scCO2. This can be attributed to the fact that the structure of the unmodified polypropylene underwent swelling during scCO2 dyeing due to high temperature and pressure which is helping in penetration of vinyl sulfone dye into the fiber.

Color fastness, along with color strength, plays an important role in dyeing performance. According to the geometric grey scale, all of the dyed PP fabrics in water and scCO2 had excellent fastness values to washing, rubbing, and light, as shown in Table 2. The light fastness of samples dyed in scCO2 medium showed a good value (rating was 4) on the blue scale, which was evident. The results of rubbing fastness showed good values (rating between 3–4 and 4). The results of washing fastness in both water and scCO2 medium were outstanding. (rating between 4–5 and 5) as shown in Table 2.

Antibacterial activity

The antibacterial activity of the dyestuff under study and the dyed PP samples were investigated against Staphylococcus aureus, Bacillus cereus, Escherichia coli, Pseudomonas aeruginosa and expressed as zone of growth inhibition ZI (mm). The antibacterial activity was determined by the agar well diffusion method given in Table 324. All tested dyestuff and treated PP samples showed positive antibacterial activities against the examined bacteria. The antibacterial activity of the unmodified PP fabrics dyed in scCO2 was significantly higher than that of the dyed fabrics in water. This can be attributed to the fact that the structure of the unmodified PP fabrics underwent swelling during scCO2 dyeing due to high temperature and pressure which helped penetration of more sulfonyl functional dye into the unmodified PP fabrics than that of the dyed fabrics in water. There was no discernible difference in the diameters of the inhibition zones for unmodified PP fabrics dyed in scCO2 before and after five washing cycles, confirming the durability of the PP fabrics dyed in scCO2.

Mechanical testing of unmodified PP fabrics

The results of elongation at break and maximum force (N) of the dyed fibers under both water and scCO2 medium were measured, and the results were reviewed in Table 4. After scCO2 dyeing there was an increase in elongation by 1.5% compared to undyed PP, while the sample dyed under water showed a decrease in elongation with a value of 8.5%. This was attributed to the fact that increasing temperature in water in presence of dispersing agent caused degradation of the polypropylene fabrics26 Alternatively, the sample dyed under scCO2 revealed a little decrease in maximum force by 7.4% while the sample dyed under water suffered from a 12% decrease. Ultimately, dyeing PP under scCO2 medium was better than dyeing in water medium because scCO2 dyeing maintained the physiochemical properties of the fiber.

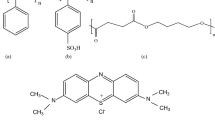

Raman spectra

Figures 7 and 8 showed the Raman spectrum and pictures of undyed and dyed PP. A Raman spectrum for undyed PP indicated several peaks. First set of peaks were observed between 900 and 1600 cm-1. The rest of peaks were located between 2700 and 4000 cm-1. The similar trend of PP spectrum was studied by Bhattacharyya et al.42.

The vinyl sulfone disperse reactive dye under study was characterized by Raman analysis and to make sure that the dyeing happened to have absorption inside or on surface of the PP fabrics. A comparison of Raman spectra for dyed and undyed PP fabrics was given in Fig. 7. Spectra were collected in the range of (100 to 4000 cm-1). The spectra were acquired using scan time settings of (3 s) and a resolution of 2.32 cm-1/ pixel for fiber analysis. Figure 7 showed Raman spectra of the undyed and dyed samples of PP fabrics where the waves assigned as follows: 1470.2 cm-1 C-H, the absorption bands at 1325–1185.8 cm-1 (-N = N-), 3045.2 cm-1 (-C = C-), 1145.2 cm-1 (SO2). The recorded Raman spectra confirmed that all the designed and expected characteristic groups were implicated in the chemical structure of the vinyl sulfone disperse reactive dye.

Conclusion

A facile one step dyeing and finishing process was constructed to dye unmodified PP fabrics with antibacterial disperse reactive dye in scCO2.The results showed that, the synthesized antibacterial vinylsulfone disperse reactive dye have high affinity for dyeing PP fabrics in water and scCO2. The K/S was enhanced using scCO2. The ratings of fastness to washing, light and rubbing ranged from very good to excellent with the increase of the depth of shade. The optimum dyeing conditions for dyeing PP in scCO2 were set to be 130 °C, pressure 25 MPa, dyeing concentration 3% at 120 min, based on the results of color strength, color fastness, and mechanical properties. Therefore, dyeing of PP fabric under scCO2 medium was proved to be effective and potential for industrial applications.

Data availability

All data generated or analyzed during this study are included in this published article [and its supplementary information files].

References

Gall, P., Danesi, S. & Simonazzi, T. Polypropylene based polymer blends: fields of application and new trends. Polym. Eng. Sci. 24, 544 (1984).

Kuo, C. F. & Chen, S. H. Functional dyeable polypropylene fabric development and process parameter optimization Part I: Dyeable modified polypropylene development with process parameter optimization. Text. Res. J. 91, 1509–1522 (2021).

Yamamoto, H. The properties of polypropylene multifilament textile. Sen’i. Gakkaishi. 61, 319 (2005).

Tehrani, A. R., Shoushtari, A. M., Malek, R. M. & Abdous, M. Effect of chemical oxidation treatment on dyeability of polypropylene. Dyes Pigm. 63, 95–100 (2004).

Miyazaki, K., Tabata, I. & Teruo, H. Effects of molecular structure on dyeing performance and colour fastness of yellow dyestuffs applied to polypropylene fibres in supercritical carbon dioxide. Color. Technol. 128, 51–59 (2012).

Miyazaki, K., Tabata, I. & Teruo, H. Relationship between colour fastness and colour strength of polypropylene fabrics dyed in supercritical carbon dioxide: Effect of chemical structure in 1,4-bis(alkylamino)anthraquinone dyestuffs on dyeing performance. Color. Technol. 128, 60–67 (2011).

Abou-Elmaaty, T. M., Abdeldayem, S. A., Ramadan, S. M., Ahmed, K. S. & Plutino, M. R. Coloration and multi-functionalization of polypropylene fabrics with selenium nanoparticles. Polymers 13, 2483 (2021).

Huang, X., Zhang, W. D. & Ma, S. B. The effect of hyperbranched polymers on the dyeing properties of polypropylene fibers. Adv Mat Res. 399–401, 1059–1062 (2011).

Sahinbaskan, B., Kocak, E. D., Merdan, N. & Akalin, M. Dyeing of polypropylene blends by using microwave energy. J. Eng. Fibers Fabr. 12, 20–27 (2017).

Toshniwal, L., Fan, Q. & Ugbolue, S. C. Dyeable polypropylene fibers via nanotechnology. J. Appl. Polym. Sci. 106, 706–711 (2007).

Abou Elmaaty, T. Chapter 20 - Recent advances in textile wet processing using supercritical carbon dioxide, The Textile Institute Book Series, Green Chemistry for Sustainable Textiles 279–299 (Woodhead Publishing, 2021).

Sorour, H., Abou Elmaaty, T., Mousa, A., Gaafar, H. & Hebeish, A. Development of textile dyeing using the green supercritical fluid technology: A Review. Mat Int. 3, 0373-0390 (2020).

Banchero, M. Recent advances in supercritical fluid dyeing. Color. Technol. 136, 317–335 (2020).

Zizovic, I. Supercritical fluid applications in the design of novel antimicrobial materials. Molecules 25, 2491 (2020).

Abate, M. T. et al. Supercritical CO2 dyeing of polyester fabric with photochromic dyes to fabricate UV sensing smart textiles. Dyes Pigm. 183, 108671 (2020).

Orhan, M., Demirci, F., Kocer, H. & Nierstrasz, V. Supercritical carbon dioxide application using hydantoin acrylamide for biocidal functionalization of polyester. J. Supercrit. Fluids. 165, 104986 (2020).

Fan, Y., Zhang, Y. Q., Yan, K. & Long, J. J. Synthesis of a novel disperse reactive dye involving a versatile bridge group for the sustainable coloration of natural fibers in supercritical carbon dioxide. Adv. Sci. 6, 1801368 (2019).

Penthalaa, R., Heoa, G., Kima, H., Leeb, I. & Kob, E. (2020). Synthesis of azo and anthraquinone dyes and dyeing of nylon-6, 6 in supercritical carbon dioxide. J. CO2 Util. 38 ,49–58 (2020).

Abou Elmaaty, T. et al. A Pilot scale water free dyeing of pure cotton under supercritical carbon dioxide. Carbohydr. Polym. Technol. Appl. 1, 100010 (2020).

Zaghloula, D. N. et al. Influence of additive organic base on dyeing of cotton fabric under supercritical carbon dioxide using fluorotriazine reactive disperse dye and investigation of optimal dyeing conditions. J. Supercrit. Fluids. 174, 05243 (2021).

Chen, Y., Niu, M., Yuan, S. & Teng, H. Durable antimicrobial finishing of cellulose with QSA silicone by supercritical adsorption. Appl. Surf. Sci. 264, 171–175 (2013).

Ayele, M., Tesfaye, T., Alemu, D, Limeneh, M. & Sithole, B. Natural dyeing of cotton fabric with extracts from mango tree: a step towards sustainable dyeing. S. Chem. Pharm. 17, 100–293(2020).

Jaxel, J. et al. Facile synthesis of 1-butylamino- and 1,4-bis(butylamino)-2-alkyl-9,10-anthraquinone dyes for improved supercritical carbon dioxide dyeing. Dyes Pigm. 173, 107991 (2020).

El-Kadi, S. M., Mahmoud, M. K., Sayed-Ahmed, K. A. & El-Hendawy, M. A. Comparison between silver nanoparticles and silver nitrate as antifungal agent. Int. J. Nanosci. Nanotechnol. 4(1), 5–1 (2018).

Abou Elmaaty, T., El-Taweel, F. & Elsisi, H. Water-free dyeing of Polyester and Nylon 6 Fabrics with Novel 2-Oxoacetohydrazonoyl cyanide derivatives under a supercritical carbon dioxide medium. Fibers Polym. 19, 887–893 (2018).

Abou Elmaaty, T., Elsisi, H., Negm, I., Ayad, S. & Sofan, M. Novel nano silica assisted synthesis of azo pyrazole for the sustainable dyeing and antimicrobial finishing of cotton fabrics in supercritical carbon dioxide. J Supercrit Fluids. 179, 105354 (2022).

Ma, J., Abou-Elmaaty, T. & Okubayashi, S. Effect of supercritical carbon dioxide on dyeability and physical properties of ultra-high-molecular-weight polyethylene fiber. Autex Res. J. 19, 228–235 (2019).

Abou Elmaaty, T. et al. Optimization of an eco-friendly dyeing process in both laboratory scale and pilot scale supercritical carbon dioxide unit for polypropylene fabrics with special new disperse dyes. J.CO2 Util. 33, 365–371 (2019).

Abou Elmaaty, T., Sofan, M., Kosbar, T., Elsisi, H. & Negm, I. Green approach to dye PET and nylon 6 fabrics with novel pyrazole disperse dyes under supercritical carbon dioxide and its aqueous analogue. Fibers Polym. 20, 2510–2521 (2019).

Abou Elmaaty, T., Elsisi, H. & Negm, I. Dyeing characteristics of polypropylene fabric dyed with special disperse dyes using supercritical carbon dioxide. Fibers Polym. 22, 1314–1319 (2021).

Abou Elmaaty, T., El-Taweel, F., Elsisi, H. & Okubayashi, S. Water free dyeing of polypropylene fabric under supercritical carbon dioxide and comparison with its aqueous analogue. J. Supercrit. Fluids. 139, 114–121 (2018).

Konduru, N., Dey, S., Sajid, M., Owais, M. & Ahmed, N. Synthesis and antibacterial and antifungal evaluation of some chalcone based sulfones and bisulfones. Eur. J. Med. Chem. 59, 23–30 (2013).

Wen, Z. H., Chao, C. H. & Wu, M. H. Aneuroprotective sulfone of marine origin and the in vivo anti-inflammatory activity of an analog. Eur. J. Med. Chem. 45(12), 5998–6004 (2010).

Madduluri, V., Baig, N., Chander, S., Murugesan, S. & Sah, A. Mo(VI) complex catalysed synthesis of sulfones and their modification for anti-HIV activities. Cat. Comm. 137, 105931–105935 (2020).

Janki, J. P., Mayur, I. M., Prakashsingh, M.C.& Kishor, H.C. Potent biological investigation into a new class of sulfone derivatives endowed with quinolinyl–cyclopropane analogue, J. Iran. Chem. Soc. 1(2022).

Upare, A. A. et al. Design, synthesis and biological evaluation of (E)-5-styryl-1,2,4-oxadiazoles as anti-tubercular agents. Bioorg. Chem. 86, 507–512 (2019).

Long, Y. Synthesis and biological evaluation of heteroaryl styryl sulfone derivatives as anticancer agents. Bioorg. Med. Chem. Lett. 26(23), 5674–5678 (2016).

Tan, T. et al. Synthesis and the biological evaluation of 2-benzenesulfonylalkyl-5-substituted-sulfanyl-[1,3,4]-oxadiazoles as potential anti-hepatitis B virus agents. Antiviral Res. 71(1), 7–14 (2006).

Holshouser, M. H., Loeffler, L. J. & Hall, I. H. Synthesis and antitumor activity of a series of sulfone analogs of 1,4-naphthoquinone. J. Med. Chem. 24(7), 853–858 (1981).

Liao, S. K. Dyeing Nylon-6,6 with Some Hydrophobic Reactive Dyes by Supercritical Processing. J. Polym. Res. 11, 285–291 (2004).

Long, J. et al. Dyeing of cotton fabric with a reactive disperse dye in supercritical carbon dioxide. J. Supercrit. Fluids. 69, 13–20 (2012).

Zheng, L. et al. Dyeing procedures of polyester fiber in supercritical carbon dioxide using a special dyeing frame. J. Eng. Fibers Fabr. 10, 37–46 (2015).

Bhattacharyya, A. R. et al. Crystallization and orientation studies in polypropylene/single wall carbon nanotube composite. J. Polym. Res. 44, 2373–2377 (2003).

Bach, E., Cleve, E. & Schollmeyer, E. Past, present and future of supercritical fluid dyeing technology—an overview. Rev. Prog. Color 88, 102 (2002).

Acknowledgements

The authors wish to dedicate this work to the soul of prof. dr. Ali Hebeish of NRC, Egypt peace upon him.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). The author(s) received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Contributions

T.A. developed the main idea and wrote the manuscript, H.S. participated in writing the manuscript did the experimental work. A.M. , H.G. synthesized the dyestuff. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abou Elmaaty, T., Mousa, A., Gaffar, H. et al. Simultaneous dyeing and antibacterial finishing of polypropylene using vinyl sulfone dye under supercritical carbon dioxide. Sci Rep 12, 8789 (2022). https://doi.org/10.1038/s41598-022-12680-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-12680-w

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.