Two things are on the rise: climate change and 3D printers in the home. Because of this, you may be wondering, is 3D printing eco-friendly?

With lots of plastic involved and printers that run for days at a time, it's unlikely that 3D printing is good for the environment.

However, you might be surprised at how 3D printing compares to old manufacturing methods and be happy to hear that there are eco-friendlier options available to you.

So, what is the environmental impact of 3D printing, and can it ever be eco-friendly?

First Off: What Is 3D Printing?

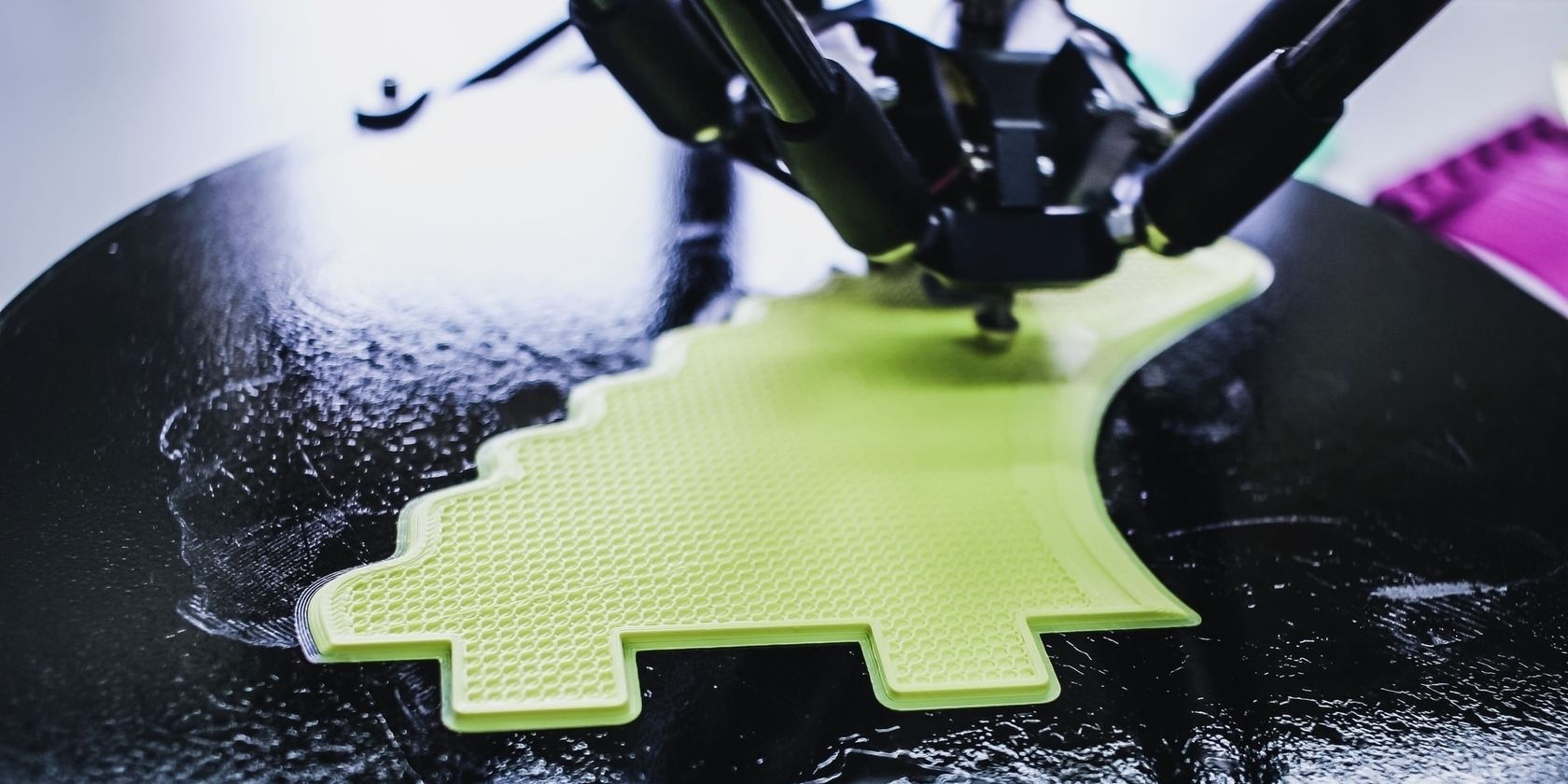

3D printing is an additive manufacturing process that builds an object layer by layer until the finished product is complete.

This is different from subtractive manufacturing which starts with, say, a block of wood and whittles it down to its final product, perhaps a wooden spoon.

One of the benefits of 3D printing as an additive process is that there is less waste. Instead of starting with a block of material, you begin from scratch, using only the necessary amount to make the object.

This is what makes 3D printing a smart choice for producing objects and a seemingly eco-friendlier option.

Should You Be 3D Printing?

All this talk of manufacturing sounds like we are mass-producing an object, right?

However, this technology is used by hobby designers and makers who love to build DIY objects from their homes.

With 3D printing, you can print souvenirs from your favorite TV show or print a computer case, making it an incredibly exciting technology. If this sounds useful or just a whole lot of fun to you, you can get started with this beginner-friendly guide to 3D printing.

But keep in mind, you are now bringing plastic objects into the world that didn't exist before, and with that power comes responsibility.

The first step is to begin by getting to know your materials.

Let's Get Filled In on Filament Types

There are several different types of 3D printers and materials. To narrow the focus, we're going to talk about one of the most popular choices: fused deposition modeling, or more commonly referred to as FDM.

The bad news is that 3D printing uses plastic filament material to print objects, and the two main types being used are ABS (acrylonitrile butadiene styrene) and PLA (polylactic acid).

The good news is that they are not created the same, and a quick comparison of their traits will highlight which one has less of an impact on the environment.

ABS

- Petroleum derivate product (oil-based plastic)

- High-temperature resistance

- Strong and durable

- Releases toxic fumes

- Does not degrade

- Non-recyclable

PLA

- Corn-based thermoplastic

- Low-Temperature Resistance

- Doesn't release fumes

- Unsuitable for durable parts

- Biodegradable over time

- Recyclable

You might have noticed that one of the two plastics is recyclable, and luckily for us, it's the most widely used filament for 3D printing: PLA.

Filament Choice Matters

Because PLA is made from a renewable source that commonly comes from corn, it has the eco-friendly trait of being recyclable and biodegradable.

That can't be said of the oil-based thermoplastic ABS, which cannot be recycled and isn't degradable.

This might make you wonder why anyone would choose ABS filament in the first place. Well, that comes down to its properties of strength and durability, which, when compared with PLA, will be far more enduring over the entire life of the object.

Think LEGO: you probably still have a box of those tiny plastic bricks somewhere, still in perfectly usable condition. That's because it's made from ABS plastic and is strong enough to last a very long time.

So, out of the two options, PLA has eco-friendlier properties, but plastics aside, there's more to consider.

What About Power Consumption?

3D printing takes time; we're talking about more than several hours and up to several days to print one object.

For example, this little sheep figurine will take just over 2 hours to print, while this moon lamp clocks in at a minimum of 3 days, during which your printer will be running the entire time. Sounds like a lot of power, doesn't it?

Despite the prolonged printing times, you'll be happy to know that the cost of running a 3D printer won't leave you with an extremely high electric bill.

It largely depends on your printer's wattage and the temperature that your design requires. For example, the Flashforge Creator Procan costs around three cents per hour to run, while the Monoprice Mini Delta can cost as little as one cent per hour to run.

This all seems reasonable but put in the context of other manufacturing processes like inkjet or machine milling, 3D printers actually consume more power. As we mentioned earlier, the flip side is that 3D printing doesn't waste nearly as much raw material.

Either way, while it may not cost you a lot of money to run a 3D printer, being aware of energy consumption and conserving electricity is overall better for our environment.

Staying Current On Your Energy Use

Most of the energy used in 3D printing comes from heating the nozzle that melts the plastic, and additionally from warming up the heated printing bed if you have one.

As we saw earlier, PLA filament melts at a lower point than ABS, thus requiring less power to print. However, if you use ABS filament for your object, you will also require a heating bed to prevent warping, adding additional heating requirements.

Choosing PLA filament is certainly the low-energy option. Still, to get an idea of how much power your prints are consuming, you should use an energy monitoring device for a detailed report.

Power Differences

Paying attention to how many watts your 3D printer uses will also give you an idea of how much energy your 3D printer uses versus other options.

To understand how 3D printers differ in power we can compare the two printers mentioned earlier. The affordable Monoprince Mini Delta uses about 60W during the printing process, while the larger and more expensive Flashforge Creator Pro uses 250W.

This demonstrates a huge difference between 3D printers available to you when considering which model might be more eco-friendly.

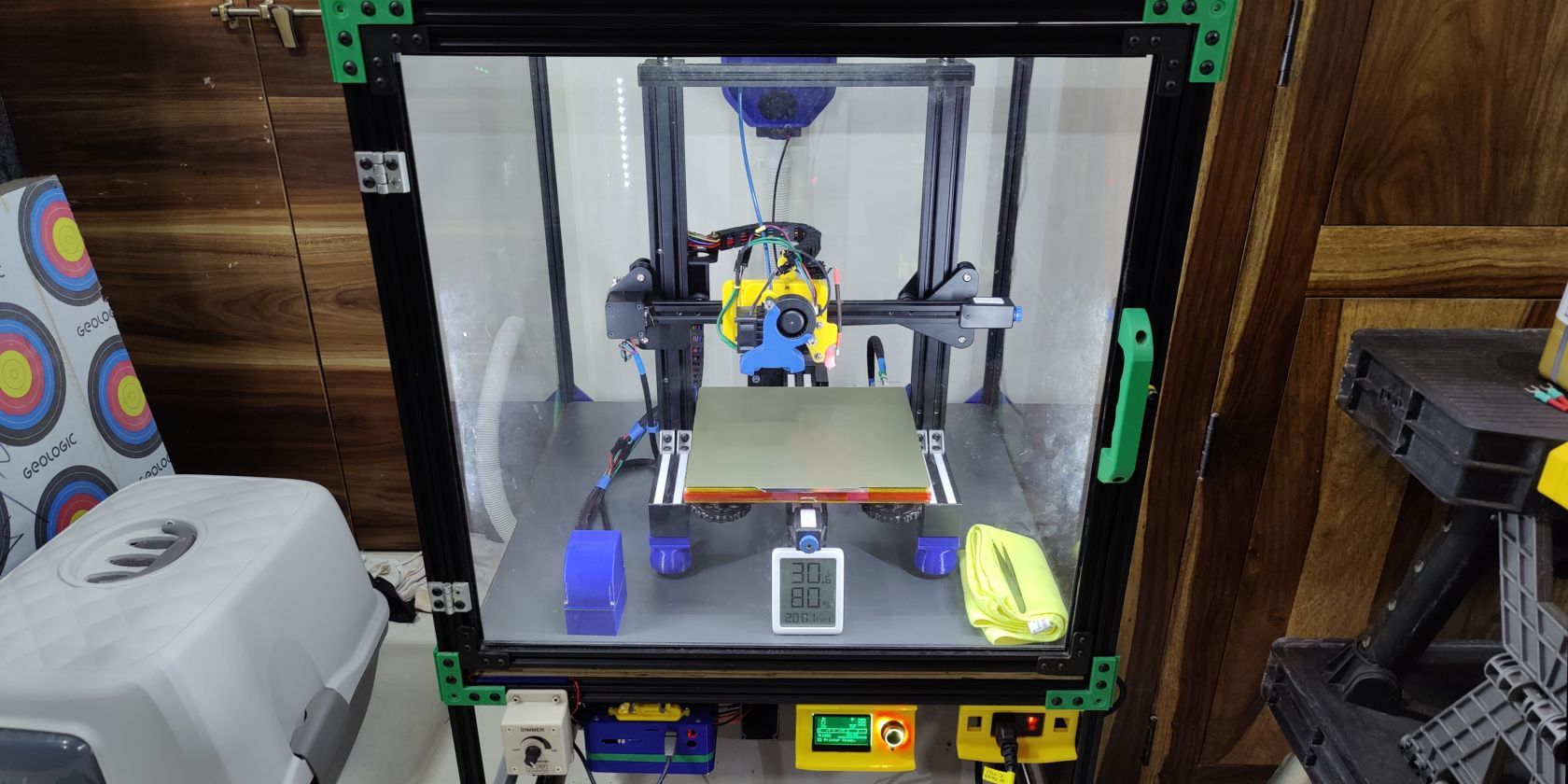

Another consideration is buying a 3D printer with an integrated closure which will help to prevent the loss of heat and lower your energy consumption further.

If you're still concerned about how much power your 3D printer will draw, however, it's worth keeping in mind that when put into the context of other electronic devices, it's still pretty energy efficient.

While the energy consumption of the two 3D printers we compared earlier ranges from 0.07 kWh to 0.24 kWh, a typical desktop computer will use about 1.05 kWh, well over four times that amount.

Object Life

Figuring out the impact of 3D printing is complex and depends on more than one factor, but one simple thing to keep in mind is, "How long will my object last?"

Creating items that are purposeful and will likely be kept for years to come will help to keep plastic from ending up in the ground unnecessarily. It's something that's easy to forget when there are thousands of cool and aesthetic designs out there to print.

When thinking about your next 3D printed object, start by asking yourself whether this is an item that you will keep for a long time, or alternatively, if it can be recycled, repurposed, or given away if you no longer want it.

So, Is 3D Printing Eco-Friendly?

Overall, the use of plastics, the power consumption of printers, and the potential for an object to have a short product life mean that ultimately, 3D printing is not entirely eco-friendly—but it's definitely headed in the right direction.

Choosing a renewable material like PLA is a better option for recycling, while advances in 3D printing technology will over time produce machines that consume less power. The process of additive manufacturing also wastes far less material than previous manufacturing methods did making it a worthwhile innovation to pursue.

With more environmentally conscious designers and makers, we're starting to see 3D printing head in a positive direction.